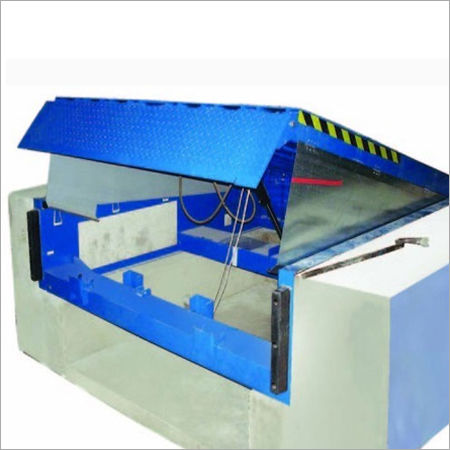

Industrial Dock Leveler

Industrial Dock Leveler Specification

- Control System

- Push Button / Remote Control

- Features

- Weather Resistant, Safety Locks

- Forklift

- Compatible

- Motor Type

- Three Phase Induction

- Equipment Type

- Dock Leveler

- Rotation Type

- Vertical Lift

- Lifting Speed

- Approx. 10-15 sec

- Condition

- New

- Lifting Capacity

- Up to 10 Tons

- Max. Lifting Load

- 10,000 kg

- Max. Lifting Height

- 600 mm

- Power Source

- Electric

- Power Consumption

- 3-6 kW

- Voltage

- 380V - 415V

- Feature

- Hydraulic Operation, Adjustable Platform

- Attributes

- Heavy Duty, Robust Construction

- Serviceability

- Easy Maintenance

- Suitable for

- Warehouses, Logistics Centers

- Lip Length

- 400 mm

- Compliance

- ISO Certified

- Finish Type

- Rust Resistant Paint

- Platform Size

- 2000 mm x 2500 mm

- Pit Size Required

- 2050 mm x 2550 mm x 600 mm

- Load Capacity Range

- 6000 kg to 20000 kg

- Ambient Temperature

- -10°C to +50°C

- Operation Mode

- Hydraulic / Electric

- Material

- Mild Steel, Powder Coated

- Noise Level

- Low

About Industrial Dock Leveler

Industrial Dock Leveler is an flexible ramp that compensates the variance in height and its designed lip arrangement on dock leveller plugs the gap between warehouses and floor of the transport vehicle for convenient movement of material and material handling applications. The equipment is proficient in loading/unloading of material in warehouses or factories/logistics centres.

Industrial Dock Leveler can lift a weight up to 8000 kg and this series is being offered with an AC power pack unit. It contains one HP motor with 3 phases 415 volts, hydraulic pump & valves of modular kind of trusted brand and hydraulic cylinder with hard chrome piston rod. It also is equipped with a control panel featuring wall mounted individual press on switch for lip and deck lip.

The design is available with a paint finish of black and golden yellow shade.

- Capacity Range : 8 MT

- Dock (LXW) : 2100 mm x 1850 mm: 2100 mm x 2000 mm,:2750 mm x 2150 mm

- Raised Height : 250 mm

- Lower Height : 300 mm

- Frame Height : 500 mm

- Applications : automobile industries, transport industries, storage area, pharma industries.

Engineered for Performance and Safety

Built with precision using mild steel and enhanced with rust resistant paint, this dock leveler achieves remarkable durability. The advanced hydraulic operation and robust construction support a load capacity of up to 20,000 kg, making it ideal for demanding industrial settings. Safety features and weather resistance ensure seamless operation in diverse working environments.

User-Friendly Controls and Easy Maintenance

The dock leveler incorporates a straightforward control system, available in push button or remote options for effortless lifting and lowering. Engineered with ease of maintenance in mind, the unit guarantees minimal downtime, high serviceability, and consistently low noise levels, ensuring hassle-free operation and longevity.

FAQs of Industrial Dock Leveler:

Q: How is the Industrial Dock Leveler operated?

A: The dock leveler operates via a hydraulic or electric mechanism, controlled through a push button panel or remote control for seamless lifting and lowering transitions.Q: What is the recommended installation process and pit size required?

A: Installation requires a dedicated pit of 2050 mm x 2550 mm x 600 mm. It is advisable to have a professional technician handle installation to ensure optimal safety, alignment, and compliance with ISO standards.Q: Where can this dock leveler be best utilized?

A: This equipment is specifically designed for warehouses, logistics centers, and loading bays, offering reliable performance where efficient loading and unloading of goods are essential.Q: What are the loading and lifting capacities of the platform?

A: The dock leveler supports load capacities ranging from 6,000 kg to 20,000 kg, with a maximum lifting capacity of 10 tons and a maximum lifting height of 600 mm, ensuring smooth handling of various material weights.Q: When is maintenance required for the dock leveler?

A: Routine maintenance checks should be conducted every 6 to 12 months, depending on frequency of usage, to ensure reliable operation and to maintain its low-noise, easy-serviceability features.Q: What are the primary benefits of using this dock leveler in your facility?

A: By utilizing this dock leveler, you benefit from enhanced operational safety, significant reduction in manual handling, time-saving hydraulic operation, and compatibility with forklifts, all contributing to efficient workflow and safety compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dock Leveler Category

Hydraulic Dock Leveler

Equipment Type : Hydraulic Dock Leveler

Feature : Easy Operation, Low Maintenance

Rotation Type : Fixed platform

Lifting Speed : Approximately 50 mm/s

Voltage : 380V

Max. Lifting Height : 600 mm