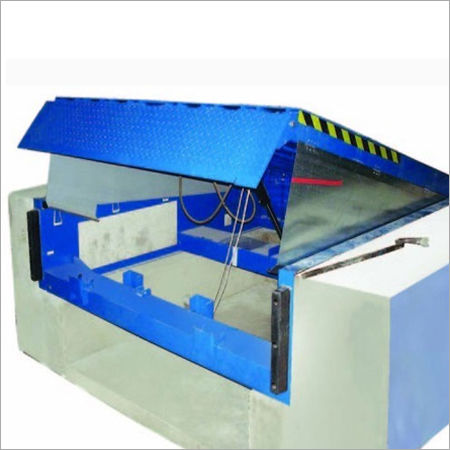

Hydraulic Dock Leveler

Hydraulic Dock Leveler Specification

- Motor Type

- Hydraulic Motor

- Control System

- Push Button Control

- Forklift

- Compatible

- Rotation Type

- Fixed platform

- Lifting Speed

- Approximately 50 mm/s

- Features

- Heavy-duty steel platform

- Equipment Type

- Hydraulic Dock Leveler

- Condition

- New

- Lifting Capacity

- Up to 10000 kg

- Max. Lifting Load

- 10000 kg

- Max. Lifting Height

- 600 mm

- Power Source

- Electric Powered

- Power Consumption

- 1.1 kW

- Voltage

- 380V

- Feature

- Easy Operation, Low Maintenance

- Attributes

- Robust construction, corrosion-resistant

- Installation Type

- Pit mounted

- Platform Size

- 2700 mm x 2000 mm

- Platform Material

- High-strength steel

- Color

- Industrial blue and yellow

- Lip Length

- 400 mm

- Hydraulic System

- Integrated single push button hydraulic system

- Application

- Loading and unloading docks, warehouses

- Safety Features

- Emergency stop, Overload protection

- Operating Temperature Range

- -10°C to 50°C

- Compliance Standards

- CE Certified

- Surface Finish

- Anti-skid, Powder Coated

About Hydraulic Dock Leveler

We are a reliable manufacturer and supplier of superlative quality Hydraulic Dock Leveler. This is a modern answer to the complicated problems of loading/unloading goods in industrial settings, factories, warehouses and logistics areas among others. It has been designed to lift the up by 300mm and down by 250mm from the floor level. It has a weight lifting capacity of up to 8000 kg and sturdily built to resistance the breakdown. Hydraulic Dock Leveler is equipped with an AC power pack unit, one HP motor with 3 phases 415 volts, valves and hydraulic pump of modular types of branded make and hydraulic cylinder featuring hard chrome piston rod. It is provided with a control panel with wall mounted independent press on switch for deck and lip.

Available with a paint finish of golden yellow and black shade.

- Capacity Range : 8 MT

- Dock (LXW) : 2100 mm x 1850 mm: 2100 mm x 2000 mm,:2750 mm x 2150 mm

- Raised Height : 250 mm

- Lower Height : 300 mm

- Frame Height : 500 mm

- Applications : pharma industries, automobile industries, warehouses, factories, transport industries.

Reliable Performance for Industrial Demands

Designed for intense loading dock applications, this hydraulic dock leveler delivers consistent, safe performance. Its strong build, corrosion-resistant coating, and heavy-duty platform mean long-term reliability even in high-traffic, heavy-load environments. Operating smoothly from -10C to 50C, its suitable for year-round usage in diverse settings.

User-Friendly and Safe Operation

Equipped with a simple push-button control system, the dock leveler is easy to operate by warehouse staff. Integrated safety features such as emergency stop and overload protection add essential peace of mind, while a non-slip surface finish ensures secure movement for forklifts and warehouse personnel.

FAQs of Hydraulic Dock Leveler:

Q: How does the hydraulic dock leveler operate?

A: The hydraulic dock leveler functions using an integrated single push button hydraulic system. Once the button is pressed, the platform smoothly lifts, allowing precise positioning and safe bridging between the dock and a truck. The hydraulic motor handles heavy loads efficiently with simple controls.Q: What maintenance is required for this dock leveler?

A: This dock leveler is engineered for low maintenance. Regular inspections of hydraulic fluid and platform integrity are recommended to ensure optimal performance. Its robust, corrosion-resistant construction and powder-coated finish minimize routine upkeep.Q: When is the hydraulic dock leveler typically installed?

A: Installation is best scheduled during setup or renovation of warehouse loading bays. As a pit-mounted unit, it requires a pre-formed pit at the site, typically done during the construction or major overhauls of facilities.Q: Where can this dock leveler be used effectively?

A: This dock leveler is ideal for warehouses, distribution centers, and logistics hubs where efficient loading and unloading of goods is critical. Its generous 2700 mm x 2000 mm platform can accommodate a wide range of vehicle types.Q: What is the process of using the dock leveler during operations?

A: To use the dock leveler, press the push button to raise the platform. The lip will extend onto the truck bed, creating a secure bridge. The forklift can then move goods safely between the dock and the vehicle. After use, retract the lip and lower the platform to its starting position.Q: What benefits does the anti-skid, powder-coated surface provide?

A: The anti-skid, powder-coated surface ensures superior grip and enhances operational safety by preventing slippage during wet or dusty conditions. The finish also increases the platforms durability and resistance to corrosion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dock Leveler Category

Industrial Dock Leveler

Max. Lifting Height : 600 mm

Rotation Type : Vertical Lift

Attributes : Other, Heavy Duty, Robust Construction

Lifting Speed : Approx. 1015 sec

Voltage : 380V 415V

Features : Weather Resistant, Safety Locks