EOT Cranes

EOT Cranes Specification

- Feature

- Corrosion Resistant, High Loading Capacity, High Performance, Low Maintenance, Long Service Life

- Loading Capacity

- As per requirement (commonly 1 ton to 100 ton)

- Crane Total Weight

- Depends on model (customized as per requirement)

- Type

- EOT (Electric Overhead Traveling) Crane

- Condition

- New

- Girder

- Single/Double Girder

- Max. Lifting Load

- Up to 100 Tons (customizable)

- Max. Lifting Height

- Up to 30 meters

- Max. Speed

- 10-20 m/min (customizable)

- Safety System

- Emergency Stop, Overload Protection, Limit Switches, Anti-collision Devices

- Span

- Up to 35 meters

- Power Source

- Electric

- Power Consumption

- Varies with capacity

- Power(W)

- Up to 30 kW (as per specification)

- Voltage

- 380V/415V/440V, 3 Phase

- Ambient Temperature Range

- -20°C to +55°C

- Painting

- Anti-corrosive Primer with Synthetic Enamel

- Material of Construction

- Mild Steel, Alloy Steel

- Compliant Standards

- IS, FEM, DIN, ISO

- Working Duty

- A3-A7 (Medium to Heavy Duty)

- Installation

- Onsite Installation Service Available

- Application

- Industrial, Construction, Warehousing, Manufacturing Units

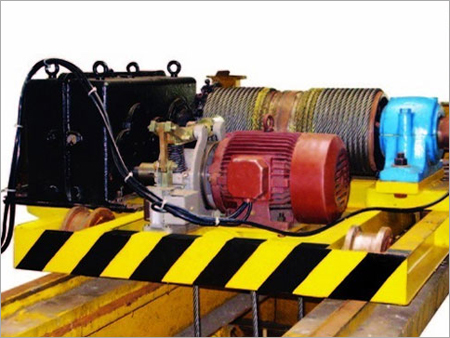

- Hoisting Mechanism

- Electric Wire Rope Hoist / Electric Chain Hoist

- Control Method

- Pendant Control, Remote Control, Cabin Control

- Operation Mode

- Manual / Semi-Automatic / Fully Automatic

- Wheel Type

- Forged Steel / Cast Steel

About EOT Cranes

EzyLift is trusted brand of EOT Cranes. We have acquired a highly reputed position in the market owing to our in-depth focus on delivering technologically superior range of cranes for bulk material handling. This crane has been designed for work at construction sites, tall building sites, metro projects, bridges and flyovers, and other such project. EzyLift EOT Cranes are demanded for efficient performance, low maintenance requirements, durability and excellent performance. This complies with all the safety norms and standards.

Features:

- Impeccable quality

- Low maintenance

- Economical prices

- Superlative designs

Versatile Control Systems

Our EOT cranes provide flexible control options, including pendant, remote, and cabin controls. Operators can choose manual, semi-automatic, or fully automatic modes to suit specific workflows and safety preferences. This adaptability enhances both productivity and user comfort across diverse industrial applications.

Superior Build and Customization

Manufactured using premium mild or alloy steel, these cranes are designed for demanding environments, featuring robust forged or cast steel wheels and corrosion-resistant finishes. With spans up to 35 meters and tailored loading capacities and speeds, our cranes are customizable to match distinct operational needs and site requirements.

Comprehensive Safety and Installation Support

Safety is paramount, with systems such as emergency stops, overload protection, limit switches, and anti-collision mechanisms. Our onsite installation services ensure swift and compliant setup, accommodating ambient temperatures from -20C to +55C and meeting IS, FEM, DIN, and ISO standards.

FAQs of EOT Cranes:

Q: How does the control method affect crane operation and safety?

A: Control methodspendant, remote, and cabinoffer various levels of operator flexibility, range, and visibility. Enhanced safety features, such as emergency stop and overload protection, are integrated regardless of the control type to ensure safe crane operation in any industrial environment.Q: What is the process for onsite installation and commissioning?

A: Once the crane is delivered, our expert technicians handle onsite installation, aligning the crane to your facilitys specifications. Installation includes system setup, comprehensive testing, safety checks, and operational training to ensure efficient and safe performance from day one.Q: When should I choose forged steel versus cast steel wheels for my EOT crane?

A: Forged steel wheels are preferred for higher durability and resistance to wear in heavy-duty operations, while cast steel wheels are suitable for moderate loads and less demanding operational cycles. Selection depends on your applications intensity and operational demands.Q: Where are these EOT cranes commonly used?

A: These EOT cranes are widely employed in industries such as construction, manufacturing units, warehouses, and general industrial settings, supporting a broad range of material handling tasks where durability and high loading capacity are vital.Q: What are the benefits of the anti-corrosive painting system on the cranes?

A: The anti-corrosive primer with synthetic enamel extends the cranes operational lifespan, guarding against rust and chemical exposure. This is especially beneficial in harsh industrial environments, reducing maintenance costs and preserving performance.Q: How customizable are the loading capacity and lifting height?

A: Both loading capacity (usually from 1 ton up to 100 tons) and lifting height (up to 30 meters) can be tailored to specific operational requirements. Our engineering team collaborates closely with clients to ensure each crane is configured for optimal workload and infrastructure compatibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Overhead Travelling Cranes Category

Over Head Cranes

Girder : Other, Single or Double Girder (as per application)

Type : Other, Overhead Traveling Crane / EOT Crane

Power Source : Electric

Condition : New

Span : Available up to 35 meters or customized

Feature : High load bearing capacity, corrosion resistance, precise construction, long operational life, and robust design.

Overhead Traveling Crane

Girder : Other, Single/Double Girder

Type : Other, Overhead Traveling Crane

Power Source : Electric

Condition : New

Span : Up to 30 meters

Feature : Robust construction, smooth operation, precision controls, easy maintenance

HOT Cranes

Girder : Double

Type : Overhead Cranes

Power Source : Electric

Condition : New

Span : 4060 feet